Wire cleaners and wire rope lubricators are indispensable in the field of repair and maintenance, where precision is crucial. These devices are essential to providing a smooth operation of cables and long-lasting life in various industries. Rope lubricators and wire cleaners are crucial for maintenance of cables. In this post, we explore their functions, advantages and the transformative impact on overall efficiency.

Understanding wire Rope Lubricators

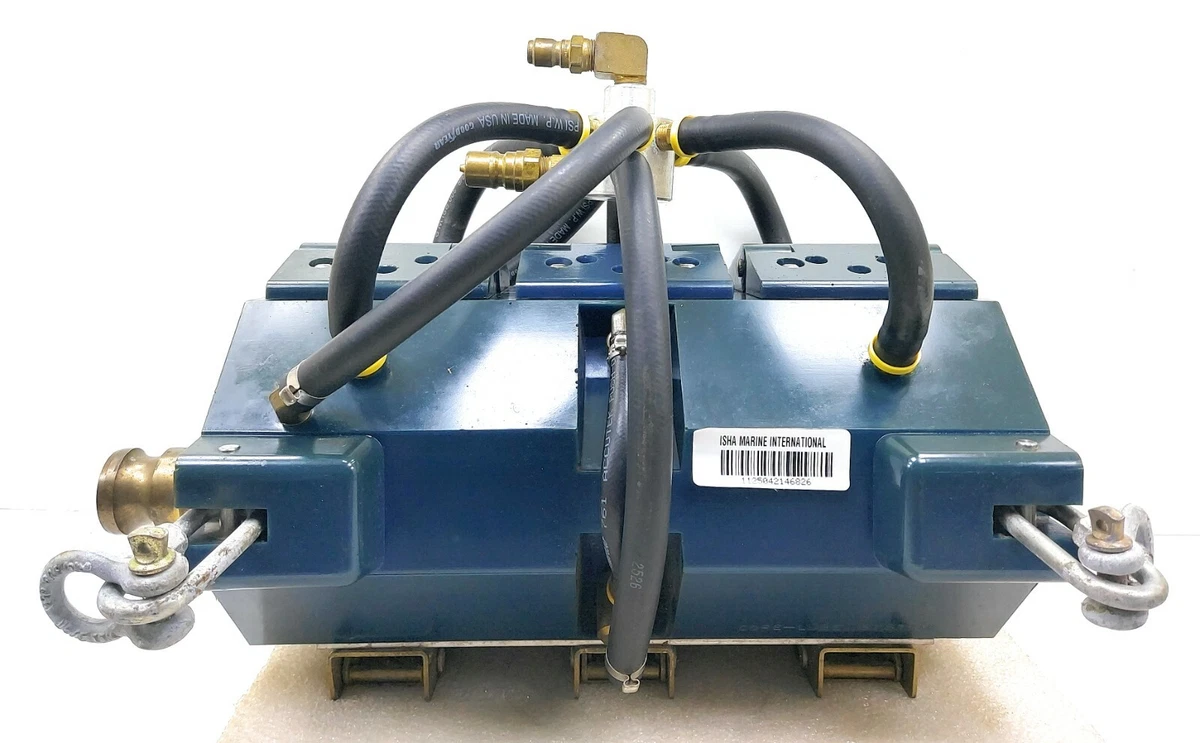

Wire rope lubricators are specialized devices that apply all-over lubrication to wire ropes. This is crucial to prevent friction and corrosion as well as extending the life of the cable. The lubricator distributes lubricant evenly throughout the length and widening of the rope wire to ensure that it is completely protected from wear.

The Role of Wire Cleaners in Cable Maintenance:

Cleaners for wires (also called cable cleansers) are essential in keeping the cleanliness and hygiene of cables. They are specifically designed to remove dirt, fluids and other contaminants that can build up on the cables during various processes. Wire cleaners are essential in harsh environments, where cables can be exposed to extreme conditions. They will ensure the best performance and help prevent harm to the cable. Click here Wire Cleaning

Optimizing Cable Lifespan:

Wire lubricators as well as wire cleaners combined can dramatically extend the lifespan of cables. Through the use of wire rope cleaning to get rid of contaminants and applying the lubrication process, cables are shielded from damaging effects like friction, corrosion, or external elements. This protects the integrity the cable and leads to improved efficiency and lower maintenance expenses.

Effectiveness of Application:

Wire rope lubricators have been designed to make use of easy and efficiency in application. They can be utilized on different types and sizes of wire ropes, allowing for flexibility in maintenance techniques for cables. Systematic and automated lubrication eliminates the risk of a poor application that manual methods might create.

Flexibility to Adapt to Challenges

The ability to adapt the wire rope cleaners and lubricators is vital in businesses that expose cables to harsh conditions. This is the case for drilling, construction, or maritime activities. They are designed to withstand harsh conditions and are therefore reliable tools to ensure the maintenance of cables in various environments.

Maintenance solutions that are affordable:

An approach that is proactive to the care of cables which includes the use of wire rope cleaners and lubricators can be a cost-effective alternative in the long run. The initial investment for these tools is minimal compared to the future costs, such as repairs and replacements because of poor maintenance.

Conclusion:

Wire cleaners and lubricators used for wire ropes are the protectors who ensure cable integrity and quality across a range of industries. A systematic lubrication process for cables and the elimination of contaminants decreases the cost of maintenance and enhances operational efficiency. The use of cables is still prevalent in critical industries, and adopting cable maintenance tools which can help maintain reliability and success is essential.